In modern industrial automation and electrical systems, precise timing control is crucial for ensuring efficiency, safety, and reliability. The Multifunction Time Relay offers a versatile solution by combining multiple timing functions into a single compact module. Unlike conventional relays that activate immediately upon receiving a signal, a multifunction time relay allows engineers to control the exact moment when outputs are triggered or released. This flexibility simplifies system design, reduces panel space, and minimizes the need for multiple separate devices.

This article explores the working principles, timing modes, technical features, applications, selection criteria, installation practices, troubleshooting tips, and maintenance strategies for multifunction time relays. It is intended for engineers, system designers, plant managers, and anyone seeking a professional, reliable timing solution for complex electrical systems.

A time relay, also known as a time delay relay, is a specialized electromechanical or electronic device designed to control the activation and deactivation of electrical circuits based on preset time intervals. Unlike conventional relays that respond instantaneously to a signal, time relays introduce deliberate delays, enabling staggered operations and coordinated sequences.

Electromechanical time relays operate via coils and mechanical contacts. When energized, the coil activates a spring-loaded mechanism that moves after a set time, closing or opening contacts. These devices are robust and well-suited for high-current switching but may have limited precision for extremely short delays.

Electronic time relays, in contrast, use integrated circuits or microcontrollers to manage timing functions. They offer high precision, longer life, and the ability to provide multiple timing modes in a single compact module. Some hybrid models combine electronic timing with mechanical contacts to handle heavy loads while maintaining accurate timing control.

Time relays are commonly used in industrial automation, lighting control, pump systems, HVAC equipment, and safety circuits where precise timing ensures operational efficiency and equipment protection.

A multifunction time relay extends the capabilities of standard time relays by incorporating multiple timing functions into a single device. Instead of using separate relays for on-delay, off-delay, interval timing, and cyclic operations, engineers can configure one multifunction relay to perform all these tasks.

Modern multifunction relays allow mode selection via rotary switches, DIP switches, or digital interfaces. Some advanced models feature programmable interfaces with display screens, enabling precise input of delay times, cycles, and intervals. This adaptability reduces inventory requirements, minimizes wiring complexity, and allows a single device to handle various operational scenarios.

The multifunction design is particularly advantageous in complex automation systems, where equipment may require different timing sequences depending on operational states, shifts, or production schedules. By consolidating multiple functions into one relay, system designers save space, reduce wiring errors, and simplify future maintenance or system expansion.

The multifunction aspect provides several critical benefits:

Space Efficiency: Consolidating multiple functions into one module reduces panel clutter and frees up space for additional equipment.

Cost Savings: Purchasing a single multifunction relay is generally more economical than buying several individual relays.

Simplified Wiring: One device can handle complex timing sequences, minimizing the risk of wiring mistakes.

Operational Flexibility: Timing modes can be changed without rewiring, making it easier to adapt to new operational requirements.

Maintenance Convenience: Fewer devices reduce points of failure, and replacement or reconfiguration is straightforward.

In essence, multifunction relays offer a “one-device solution” to complex timing problems, making them ideal for modern industrial and commercial applications.

A multifunction time relay consists of three primary components: a timing circuit, a trigger mechanism, and output contacts. When a triggering signal is applied, the timing circuit counts the preset interval, and depending on the selected mode, the output contacts either close, open, or cycle in a defined pattern.

Electronic multifunction relays use integrated circuits to generate highly accurate timing intervals, often adjustable down to milliseconds. Electromechanical relays rely on mechanical arms and springs that move after the coil is energized, suitable for high-load switching. Hybrid models may combine precise electronic timing with mechanical contacts to deliver the best of both worlds: accuracy and load-handling capacity.

Some multifunction relays include LED indicators or small displays to visually indicate timing status, allowing quick confirmation during installation or troubleshooting. Others offer digital programming, which can include memory storage for multiple timing configurations, ensuring consistency in repetitive operations.

Multifunction relays support a range of timing modes:

On-Delay (Delay-on-Make): Activates the output after a preset delay once the trigger is applied. Ideal for staggered motor startups or delayed lighting sequences.

Off-Delay (Delay-on-Break): Closes the output immediately when triggered but opens it after a defined delay once the signal is removed, often used for ventilation fans or warning alarms.

Interval Timing: Maintains the output in an energized state for a specified duration and then automatically deactivates. Useful in water pumps, dosing systems, and timed production processes.

Cyclic / Repeating Mode: Alternates between ON and OFF states at regular intervals, suitable for repetitive operations, flashing signals, or rhythmic motor cycles.

Pulse Generation: Produces a fixed-duration output pulse upon triggering, useful for control signals, sequencing, or test cycles.

Retriggerable vs Non-Retriggerable Modes: Retriggerable relays extend or reset timing intervals when a new signal is received, while non-retriggerable models complete the cycle before accepting a new trigger.

These versatile modes enable a single device to manage a wide range of timing applications, reducing the need for multiple relay types in a control panel.

Modern multifunction relays offer adjustable time ranges from milliseconds to hours. Many devices provide coarse and fine adjustment controls, allowing precise selection of delay times. Digital models may offer programming via push-buttons, rotary dials, or even software interfaces.

Visual indicators like LEDs or displays allow operators to verify timing operation in real-time. The wide adjustment range ensures that the same relay can serve both rapid cycling applications, such as conveyor motors, and long-duration processes, like irrigation or chemical dosing.

When selecting a multifunction time relay, understanding the essential technical features is critical to ensure reliable performance and long-term durability.

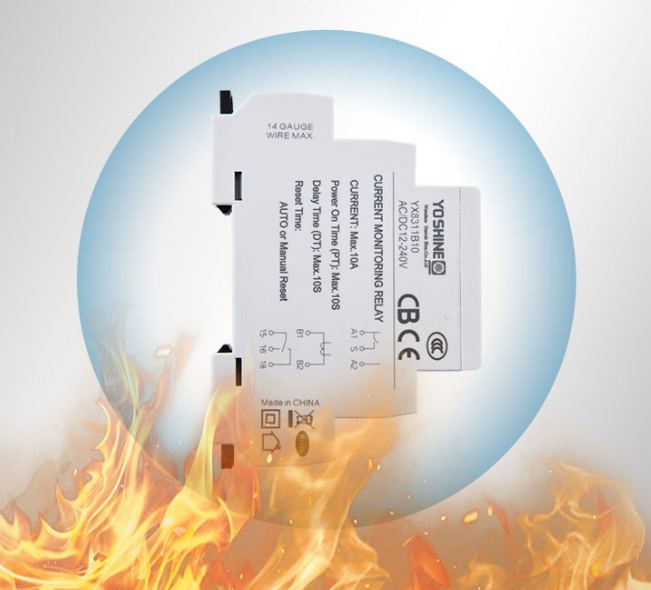

A wide supply voltage range is one of the first attributes to consider. Many modern relays support both AC and DC voltages across broad ranges, such as 24–240 V, allowing the same device to be used in different systems without compatibility issues. This flexibility reduces the need to stock multiple models and simplifies system design.

The number and variety of timing modes are equally important. Look for devices that provide on-delay, off-delay, interval, cyclic, pulse, and retriggerable modes. User-friendly mode selection, such as rotary switches or digital interfaces, allows quick adaptation to different operational requirements without rewiring. Some advanced models even offer programmable memory settings, enabling engineers to store multiple configurations for different processes.

Precision in timing adjustment is another vital feature. Relays with coarse and fine tuning, or digital programming capabilities, enable exact control over timing intervals. This is essential for processes requiring tight synchronization, such as conveyor lines, multi-stage pumps, or HVAC systems with coordinated start-stop sequences.

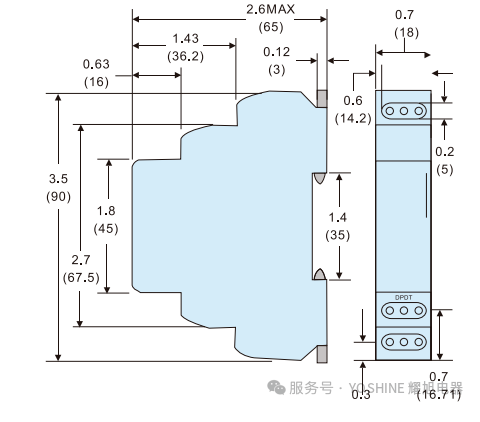

Compactness and mounting options also play a significant role. DIN-rail mounted multifunction relays with narrow widths conserve panel space while remaining accessible for wiring and maintenance. Clear labeling, push-in or screw terminals, and visible status indicators make installation straightforward and reduce the likelihood of errors during commissioning.

Durability and environmental resilience are critical, particularly in industrial settings. Relays must withstand temperature variations, vibration, dust, and moisture. Devices rated with appropriate IP levels, vibration resistance, and mechanical robustness ensure reliable operation over extended periods. Additionally, safety certifications such as CE, UL, or RoHS compliance demonstrate adherence to international standards, providing peace of mind and facilitating regulatory approvals in commercial installations.

Finally, multifunctionality itself is a key feature that guarantees adaptability and future-proofing. A single relay capable of multiple timing operations reduces the need for hardware replacement as system requirements evolve, supporting scalable and flexible automation designs.

In industrial environments, precise timing is essential to synchronize machinery, control motor start-up sequences, and prevent equipment overload. Multifunction time relays allow engineers to implement complex sequences using fewer components, streamlining control panels and reducing wiring complexity. For example, in a packaging line, a relay can stagger conveyor motors, actuate robotic arms, and manage pneumatic valves in precise intervals, ensuring smooth production flow.

The ability to switch between different timing modes within a single module adds further flexibility. If production requirements change, engineers can reconfigure the relay without replacing hardware or rewriting control logic, saving both time and cost. Multifunction relays also simplify maintenance, as fewer devices mean fewer potential failure points and easier troubleshooting.

Heating, ventilation, and air conditioning systems benefit greatly from multifunction time relays. Fans, compressors, and dampers often require delayed activation to prevent simultaneous loads from drawing excessive power. Interval or cyclic timing modes help maintain temperature and airflow within target ranges efficiently.

For example, a multifunction relay can manage a staggered fan start-up in a multi-zone HVAC system, reducing electrical stress and energy consumption. Cyclic modes may be used to ventilate rooms at regular intervals, maintaining air quality while minimizing unnecessary runtime. Digital adjustment features allow facilities managers to fine-tune timing based on occupancy patterns, further optimizing energy usage.

In commercial and industrial lighting applications, multifunction relays provide precise control for timed illumination, flashing signals, and energy-saving automation. On-delay and interval modes can ensure that lights turn on only when needed and switch off automatically after a set period.

Flashing or cyclic functions are useful for signaling or decorative purposes, such as warning lights in factories or rhythmic lighting sequences in public spaces. The ability to adjust timing easily allows facility managers to adapt lighting schedules for different shifts, seasons, or operational scenarios, contributing to energy efficiency and cost savings.

Multifunction relays are particularly advantageous for water management, chemical dosing, and irrigation systems. Timed activation prevents overloading pumps, staggers operation across multiple units, and ensures that fluids are delivered precisely when needed. Interval timing maintains consistent flow, while cyclic modes can manage repetitive pumping operations.

For example, in a water treatment facility, a multifunction relay can coordinate multiple pumps, control chemical injection intervals, and manage aeration cycles, ensuring efficient and safe system operation. Retriggerable modes are particularly useful for systems that require intermittent operation triggered by fluctuating sensor signals, maintaining flexibility while preventing equipment damage.

In emergency and safety systems, precise timing is critical. Multifunction relays control the duration and sequence of alarms, warning lights, or sirens. On-delay, off-delay, and pulse modes ensure alerts are triggered correctly, sustained for the required period, and deactivated reliably.

For example, a fire alarm system may require a brief initial pulse to activate signaling devices followed by cyclic flashing until reset. Using a multifunction relay reduces the need for multiple single-function devices, simplifying system design while ensuring compliance with safety protocols. These relays also provide predictable operation in critical situations, enhancing reliability.

Although commonly used in fixed installations, multifunction time relays are also effective in vehicles, agricultural machinery, and mobile equipment. They can manage intermittent lighting, wiper operation, auxiliary device sequencing, or engine startup delays. Compact, robust models allow integration into confined spaces, maintaining precise timing even under vibration and varying temperatures.

For instance, a multifunction relay could control the timed operation of fuel pumps, cooling fans, and warning signals in agricultural machinery, ensuring coordinated performance and prolonging component lifespan. Their adaptability makes them ideal for diverse mobile applications where precise timing contributes to operational safety and efficiency.

The first step in selecting a suitable relay is to clearly define operational timing requirements. Determine which functions are needed—on-delay, off-delay, interval, cyclic, or pulse—and consider whether retriggerable or non-retriggerable operation is required. Evaluate the precision needed for specific processes, from rapid cycles to extended delays, and anticipate future operational changes. This clarity ensures that the selected relay meets both current and evolving system demands.

Select a relay compatible with the system’s supply voltage type (AC or DC) and range. Many multifunction relays operate over wide voltage ranges, accommodating multiple systems and reducing the need to stock different models. Ensuring proper voltage compatibility avoids malfunctions, timing drift, and potential damage to the device or controlled equipment.

The relay’s output contacts must match the electrical characteristics of the controlled load, including voltage, current, and type (resistive, inductive, or capacitive). Verify the contact configuration—normally open (NO), normally closed (NC), or changeover (SPDT)—to ensure proper integration. Inductive or capacitive loads may require additional protective elements, such as diodes or contactors, to extend relay life and maintain reliable operation.

Assess the operating environment, including temperature, humidity, vibration, dust, and exposure to contaminants. Choose relays with adequate mechanical strength and environmental protection ratings (IP levels) suitable for the installation site. Additionally, consider the panel layout, available space, and mounting method, ensuring easy access for wiring and maintenance.

A relay with intuitive mode selection, clear timing adjustment controls, and visible status indicators simplifies commissioning and reduces human error. Digital interfaces with memory storage further enhance flexibility, allowing pre-programmed configurations to be quickly applied or modified as operational needs change.

Opting for a multifunction relay with a broad range of timing modes and adjustment options ensures adaptability to future system changes. A single device capable of evolving with operational demands reduces replacement costs and simplifies upgrades in complex automation systems.

Despite their robust design, multifunction time relays may experience issues due to wiring errors, environmental stress, or component wear. Common problems include:

Failure to trigger or delayed activation: Often caused by incorrect wiring, insufficient supply voltage, or damaged input signals. Double-check connections and voltage levels.

Erratic cycling or incorrect timing: Could result from improper mode selection, mechanical wear (in electromechanical models), or environmental interference. Verify mode settings and ensure the device is protected from vibration or electromagnetic noise.

Output contact failure: High inrush currents or inductive loads without protection may damage contacts. Incorporate contactors or protective circuits as recommended.

Display or indicator malfunction: Typically associated with digital models exposed to extreme temperatures or moisture. Ensure the relay operates within specified environmental limits.

Routine inspection prolongs the life and reliability of multifunction relays. Visual checks should confirm terminals are secure, indicators are functioning, and no signs of overheating or mechanical wear are present. For electromechanical models, occasional cleaning and lubrication of moving parts may be necessary, following manufacturer instructions.

Testing timing accuracy periodically ensures the relay maintains proper intervals, especially in critical applications. For digital relays, check programming settings and memory retention, updating configurations as operational requirements change. Environmental monitoring, such as temperature and humidity checks, helps prevent premature component degradation.

Maintaining accurate records of relay installation, configuration, testing, and maintenance activities aids in troubleshooting and system audits. Documenting wiring diagrams, operational modes, and adjustment values ensures consistency across maintenance cycles and allows technicians to quickly replicate or modify configurations in multiple installations.

By consolidating multiple timing functions into a single device, multifunction relays reduce panel space, wiring complexity, and hardware costs. This integration streamlines system design and allows engineers to implement sophisticated timing sequences without the need for multiple separate relays. Reduced component count also simplifies maintenance, minimizing downtime and associated labor costs.

The ability to switch between various timing modes and adjust delay intervals on demand provides unmatched operational flexibility. Systems can adapt to changing production requirements, seasonal adjustments, or evolving safety protocols without hardware replacement. Retriggerable features further enhance adaptability, supporting dynamic processes triggered by variable signals.

High-quality multifunction relays, rated for industrial environments and certified for safety compliance, provide reliable operation in critical systems. Accurate timing prevents equipment overload, ensures proper sequencing, and contributes to operator and system safety. Durable construction withstands vibration, dust, and temperature extremes, reducing failure rates and extending service life.

Fewer devices, standardized interfaces, and clear status indicators simplify maintenance and fault diagnosis. Technicians can identify issues quickly, adjust timing settings as needed, and replace units without disrupting overall system operation. Predictable behavior and robust design reduce unplanned downtime and improve overall system reliability.

Multifunction relays are applicable across a wide range of industries, including industrial automation, HVAC, lighting, fluid handling, safety systems, and mobile equipment. Their adaptability ensures that a single product line can meet diverse operational requirements, supporting scalable and future-ready system designs.

The multifunction time relay represents a critical advancement in modern timing control, combining precision, flexibility, and reliability in a single compact device. Its wide range of timing modes, adjustable intervals, and robust construction make it suitable for industrial automation, building management, energy-efficient lighting, fluid handling systems, safety and signaling applications, and mobile equipment. By consolidating multiple timing functions into one device, engineers achieve cost savings, simplified wiring, and operational efficiency, while maintaining high safety and reliability standards.

Proper selection, installation, and maintenance practices ensure the relay delivers consistent performance over time, adapting seamlessly to evolving operational requirements. For engineers and system designers seeking a versatile, durable, and efficient timing solution, the multifunction time relay provides a proven and professional choice.